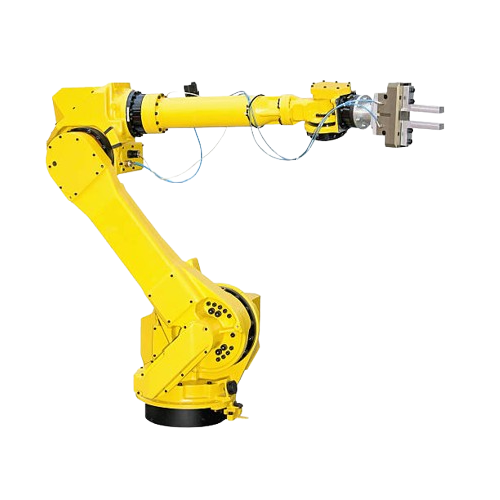

Pick & Place

Imagine a robotic arm moving like a shadow over the lines that control the pulse of manual production: its sensors recognize objects, calculate their positions, and with the composure of an unthinking intelligence, it picks up parts and places them precisely. Pick & Place automation operates like an invisible orchestra conductor, combining speed and consistency in production lines. It reduces the margin of error, frees up labor from repetitive tasks, and transforms production into a rhythmic dance.

Speed, Precision, and Efficiency

The true appeal of Pick & Place systems is their ability to produce repeatable movements in seconds. Cameras, laser scanners, and AI-powered algorithms allow them to distinguish objects by size, shape, color, or location. This provides a turbocharged effect to production lines in the food, electronics, and logistics sectors. Quality is maintained without slowing down; the line flows without stopping.

Flexibility and Industry 4.0-Compatible Structure

Modern Pick & Place robots are no longer just mechanical arms; It can adapt to new product types with software updates, report production data in real time, and even communicate wirelessly with other machines. This offers businesses less downtime, lower costs, and virtually unlimited scalability. In short, for anyone looking to secure a place in the factory of the future, Pick&Place automation is no longer a luxury but a basic necessity.

Contact Us

Contact us to discover our automation solutions and expertise in custom machine manufacturing. Send us your questions, suggestions, or project requests; our expert team will respond as soon as possible and be here to provide the best solutions for your needs!

Our Goal: To Bring Excellence in Service and Innovation